IF YOU MEASURE IT, YOU CAN IMPROVE IT

Need to better understand what happened downhole during operations? Guidehawk records downhole events to deliver data-rich insights that help decision making to improve future performance. Guidehawk records strain, pressure, temperature, shock and tool orientation delivering actionable insights in a comprehensive post-job report. This multi-purpose tool can verify the shifting of sleeves, setting plugs and monitor pressure when fracturing. Guidehawk give the operator the ability to identify potential well integrity issues and help mitigate risks.

FEATURES

Guidehawk’s sensors measure:

Pressure

Strain

Shock

Temperature

Tool orientation

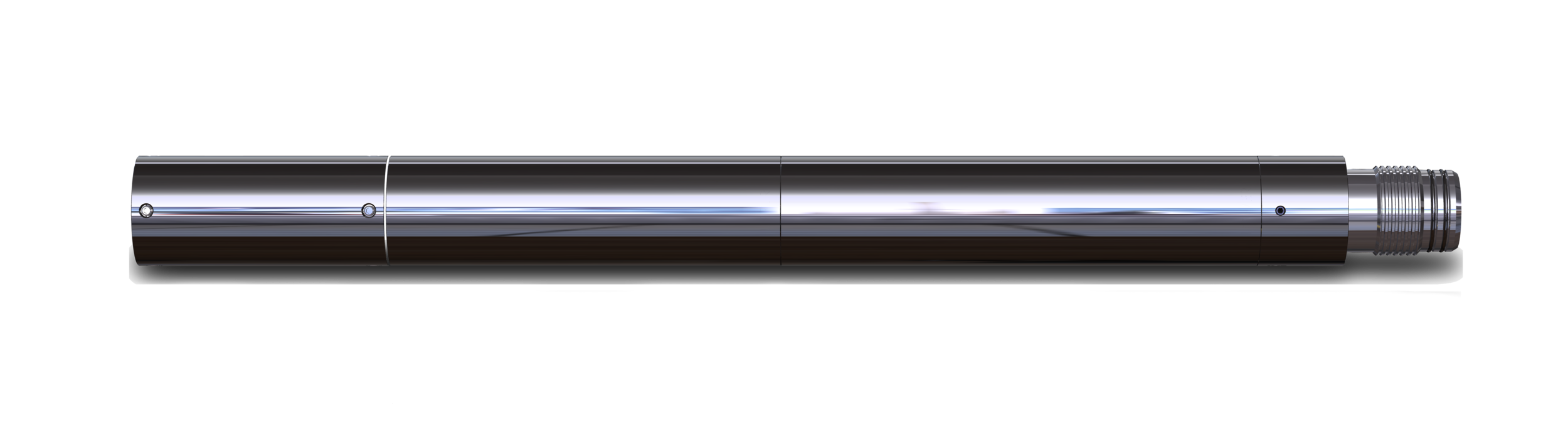

Annular Flow- Guidehawk

Through Tubing - Guidehawk

BENEFITS

Verify and analyze downhole events such as shifting sleeves or setting plugs.

Rental options available

APPLICATIONS

Fracturing

Setting plugs

Shifting sleeves